Renewable Energy for Food Preparation and Processing - WISIONS

WISIONS FOOD ISSUES: Renewable energy for food preparation and processing

In a report of the WISIONS Technology Radar from 2011 - published by a Wuppertal Institute Initiative -key findings on energy solutions for the preparation and processing of food are presented, using local and renewable energy resources. The focus of the study lies on the domestic usage of stoves and certain post harvesting technologies.

The preparation and processing of food could not be done without the use of energy: frying, boiling, baking, drying, refrigerating, milling - all need energy to work. The central problem with most food preparation techniques is their inefficient and pollutant use of renewable energies. To conquer this problem, some designs have been developed to prepare and process food more efficiently and productively. The WISIONS Technology Radar introduces the reader to the most important technologies by using case studies obtained from developing countries.

Energy for Cooking Food

Preparation of food is one of the main energy needs of households in developing countries. The most common ways to prepare food in these countries are rather inefficient and often even unhealthy for their users. The following designs present some solution concepts for more sustainable energy-technologies for cooking:

Solid Biomass Stove

Newly designed stoves that improve the combustion of biomass, are therefore much more energetically efficient and can reduce the pollution of indoor areas significantly. As this technology is comparably cheap, easy to manufacture and handle, it is the most accessible option for many households in developing countries. The design (i.e. the size and dimensions of the combustion chamber) of an improved stove depends to a great amount on what biomass is used to fire the stove. Therefore, there are many different designs suitable for burning almost all kinds of solid biomass. The type of fuel available in a region determines the types of stoves to be promoted. Through the use of more efficient stoves, the pressure on valuable biomass resources can be reduced. An interesting new aspect is the development of so called “micro-gasification” i.e. applying the principle of gasification for cooking. This technology provides significant advantages: different kinds of biomass residues, which are not traditionally used as fuel for cooking, could be used through new treatments; the process can be more efficient and cleaner compared to the direct combustion of biomass; and it offers the option to generate (bio-) charcoal as a by-product which serves as a substrate for soil recovery or enhancement.

A case study evaluating a project conducted from 2007-2008 in Laos, demonstrated the usefulness of improved biomass stoves concerning their cost effectiveness and eco friendliness. The key to the success of this project was the strong support from the local authorities and the village.

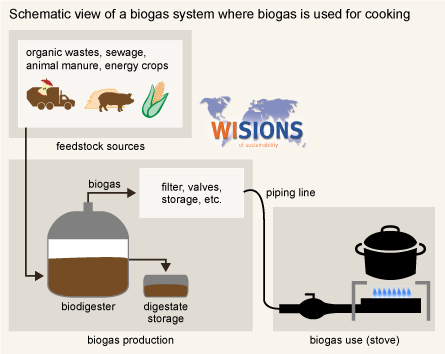

Biogas Stove

These stoves use biogas as fuel, which is a gas mixture containing methane and can be generated by anaerobic digestion. Where fenced animal husbandry and cattle is existent, they are used under the best circumstances. The production of biogas is a relatively complex process, in which biomass such as dung and manure is converted into biofuel. The use of the biogas for cooking or baking is comparatively easy. The anaerobic digestion is the key process. The optimal production of biogas depends on various factors, which, if neglected, can significantly reduce the generated amount of biogas. Generally, the users of a biogas combustor generate their own biogas by using available organic waste. To do this properly, regular feeding of the combustor is necessary. That means that users have to change their traditional practices under certain circumstances, for example from nomadism to agricultural business.

A case study reviewed a project, which has been conducted from 2007-2010 in Kenya. It resulted in the successful implementation of three biogas systems. Calculating the cost effectiveness of the systems showed that the savings from firewood will refinance the systems within 2 or 3 years.

Solar Cooker

Solar cookers use the radiation of the sun to heat and boil food. The technology can be used best in regions where it is very dry and high levels of sunlight can be expected. To ensure the best implementation of these cookers, local cooking habits and social conditions must be taken into account. There are many different forms of solar cookers and most of them follow three basic principles:

The Solar Concentrator - a reflecting material, such as aluminium facets in the form of a parabolic mirror, which reflects bundled solar radiation directly onto the cooking pot

The Box Cooker - consisting of an opentopped insulated box that is coloured black on the inside, with one or two pieces of glass or transparent plastic covering the top of the cooker. It can reach moderate to high temperatures, with maximum temperatures of about 180°C

The Solar Panel Cooker – integrates elements of both box and parabolic cookers. A metallised cardboard reflector is folded into a bowl or multi-facet shape, concentrating the sunlight onto a dark coloured pot, which is situated in a transparent plastic bag that acts as a heat trap.

When the climatic conditions are suitable, solar cooking and baking solutions can be recommendable complementary technologies that can significantly reduce the demand for other energy sources.

A pilot project in Argentina conducted with the help of micro-financing resulted in 40 families cooking with solar power, i.e. solar panel systems. The families now benefit from the use of clean and sustainable energy for cooking.

Solar cookers used for baking are called solar ovens. These ovens operate after the same principles that solar cookers do, but instead of directly heating up the groceries, air is warmed up and used for baking. In this process, all available solar techniques can be used.

Other Techniques

Using liquid biofuel is a possible source of energy, but this process and its potential impacts would need to be critically analyzed.

Energy for Processing Food

Great shares of a crop can get lost due to incorrect post-harvest treatments and transport. The correct dealing with crops is a key component in agricultural production. Through the use of renewable energies, huge potentials to improve the postharvest treatment of produce exist. However, until today, only niche specific concepts exist and to develop these ideas into more robust solutions, innovative efforts are needed. The most common ways to preserve crops and their flaws are:

Drying

is fruit from which the majority of the original water content has been removed either naturally, through sun drying, or through the use of specialized dryers. This practice of preserving food and other agricultural products has been common for centuries. Recently designed solar dryers are more efficient than traditional methods and prevent the crops from getting damaged by insects. However, most of the dryers are badly manufactured and do not perform well. The maintenance and repair of the mostly unique designs require greater than ordinary technical skills. Thus, only a moderate number of solar dryers are currently in use globally. All of the dryers follow the same basic principles and consist of three main components:

i) a drying chamber in which the food is laid out

ii) a solar collector that heats the air

iii) some type of airflow system

The various types of solar dryers can be grouped into different categories (1 & 2) depending on two parameters: Whether or not they have a forced air circulation and if they use the solar power directly or indirectly.

1a) The direct use of solar power sees the fruits directly exposed to solar radiation; it is suited for fruits where a colour change is acceptable, furthermore it is cheap and simple to construct

1b) The indirect use of solar power consists of separate solar collectors and drying chambers; it is suited for fruits where there is no acceptance for colour change and the loss of vitamins, but they are much more expensive and complex to build

2a) Natural Air Convection uses the chimney effect to create a flow of dry air; it is very simple and cheap but only allows small quantities of fruit to be dried at a time; the flow of the air cannot be effectively controlled and the drying process is slow

2b) Forced Air Circulation uses an electric fan to create a flow of dry air; it is clearly more expensive and more difficult to operate, but permits a greater amount of control over the airflow and shorter drying durations

A case study consisting of a pilot project in Afghanistan showed the usefulness of so-called tunnel-dryers, while drying tomatoes and apricots: 7 kg raw-material where dried to 1 kg dried products within 4 days. However, it was clear by the end of the project that the dryers were to expensive. But it could be possible that installed dryers of different specifications would prove to be more economically viable.

Refrigeration

Solar refrigeration technologies use solar power to run a cooling system. In areas with a high degree of solar radiation and low supply of electricity, solar powered refrigerators can be a suitable solution for the cooling of food and vaccines as well as medicines. There are mainly two different kinds of solar refrigerators: Solar PV Refrigerators and Solar Thermal Refrigerators. In a Solar PV refrigerator, there is a photovoltaic system which runs a conventional refrigeration device. In a Solar Thermal Refrigerator, solar heat is being used to generate the cooling effect. Among several methods that enable the use of heat to run a refrigerator, the absorption refrigeration cycle is the most commonly applied one.

Thermal refrigerators can also use heat generated by biogas to operate. When doing so, they need about 3000 liters of biogas per day.

Another system of cooling, suitable for hot and dry regions, is the construction of an evaporative cooling device: A container with groceries is placed inside a wet material; the evaporation process detracts energy in form of heat from the container with the food.

At present, there are around 1.5 billion refrigerators in use globally. Around 100 million units have been recently produced per year. In contrast, there are some 3000 medical solar refrigerators, which have been installed. But they still cannot compete in terms of cost or efficiency with the well-established designs.

Milling and Pressing

Extracting oil from crops produces a very valuable product, which is on the one side a very healthy one and can be sold on the other side for high prices on local markets. Improving old designs of wind- and water-powered mills and presses by using diesel and electrical power has been a common practice. The next step further could be the use of renewable energies instead of the pollutant use of fossil fuels. For example, a biogas system could power a special engine for milling, or a conventional engine could run on plant oil.

Further Information

on energypedia

- Water and Energy for Food (WE4F) portal on energypedia

- Productive Use Portal on energypedia

- Solar Cookers

- Milling

- Cooling for Agriculture

More information is available on the internet platform

and under:

- http://www.giz.de/fachexpertise/html/15422.html, website of the HERA-Project of the GIZ

- http://www.giz.de/fachexpertise/html/2556.html, Energy-Newsletter of the GIZ

- https://energypedia.info/wiki/Main_Page, Energypedia-Wiki-Platform

- https://energypedia.info/wiki/Portal:Water_and_Energy_for_Food, the Water and Energy for Food portal on Energypedia, a project of the GIZ

- http://agriwaterpedia.info/wiki/Main_Page, Agriwaterpedia, a project of the GIZ