Technical Aspects of Grid Interconnection

Technical Aspects of Grid Interconnection

2.1. Introduction

2.1.1. The Evolution of Interconnected Systems

Electricity grid interconnections have played a key role in the history of electric power systems. Most national and regional power systems that exist today began many decades ago as isolated systems, often as a single generator in a large city. As power systems expanded out from their urban cores, interconnections among neighboring systems became increasingly common . Groups of utilities began to form power pools, allowing them to trade electricity and share capacity reserves. The first power pool in the United States was formed in the Connecticut Valley in 1925 . As transmission technologies improved, long distance interconnections developed, sometimes crossing national borders. The first international interconnections in Europe came in 1906, when Switzerland built transmission links to France and Italy. One of the great engineering achievements of the last century has been the evolution of large synchronous alternating current (AC) power grids, in which all the interconnected systems maintain the same precise electrical frequency. Today, the North American power system is composed of four giant synchronous systems, namely the Eastern, Western, Texas, and Quebec interconnections. The Eastern interconnection by itself has been called the largest machine in the world, consisting of thousands of generators, millions of kilometers of transmission and distribution lines, and more than a billion different electrical loads. Despite this complexity, the network operates in synchronism as a single system. So does the Western European interconnection, which reaches from the UK and Scandinavia to Italy and Greece, embracing along the way much of Eastern Europe (for example, Poland, Hungary, Slovakia, and the Czech Republic). Synchronous interconnections among countries are expanding in Central and South America, North and Sub-Saharan Africa, and the Middle East10. At the same time that synchronous AC networks have reached the continental scale, the use of high voltage direct current (HVDC) interconnections is also rapidly expanding as a result of technical progress over the last two decades. HVDC permits the asynchronous interconnection of networks that operate at different frequencies, or are otherwise incompatible, allowing them to exchange power without requiring the tight coordination of a synchronous network. HVDC has other advantages as well, especially for transmitting large amounts of power over very long distances. Fundamentals of both AC and DC interconnections are discussed below in Sections 2.2, 2.3, and 2.4 of this Chapter.

2.1.2. General potential benefits of grid interconnections

There are number of technical rationales for grid interconnections, many of which have economic components as well (as described in Chapter 3 of this Report). Technical rationales for grid interconnection include: • Improving reliability and pooling reserves: The amount of reserve capacity that must be built by individual networks to ensure reliable operation when supplies are short can be reduced by sharing reserves within an interconnected network. • Reduced investment in generating capacity: Individual systems can reduce their generating capacity requirement, or postpone the need to add new capacity, if they are able to share the generating resources of an interconnected system. • Improving load factor and increasing load diversity: Systems operate most economically when the level of power demand is steady over time, as opposed to having high peaks. Poor load factors (the ratio of average to peak power demand) mean that utilities must construct generation capacity to meet peak requirements, but that this capacity sits idle much of the time. Systems can improve poor load factors by interconnecting to other systems with different types of loads, or loads with different daily or seasonal patterns that complement their own. • Economies of scale in new construction: Unit costs of new generation and transmission capacity generally decline with increasing scale, up to a point. Sharing resources in an interconnected system can allow the construction of larger facilities with lower unit costs. • Diversity of generation mix and supply security: Interconnections between systems that use different technologies and/or fuels to generate electricity provide greater security in the event that one kind of generation becomes limited (e.g., hydroelectricity in a year with little rainfall). Historically, this complementarity has been a strong incentive for interconnection between hydro-dominated systems and thermal-dominated systems. A larger and more diverse generation mix also implies more diversity in the types of forced outages that occur, improving reliability. • Economic exchange: Interconnection allows the dispatch of the least costly generating units within the interconnected area, providing an overall cost savings that can be divided among the component systems. Alternatively, it allows inexpensive power from one system to be sold to systems with more expensive power. • Environmental dispatch and new plant siting: Interconnections can allow generating units with lower environmental impacts to be used more, and units with higher impacts to be used less. In areas where environmental and land use constraints limit the siting of power plants, interconnections can allow new plant construction in less sensitive areas. • Coordination of maintenance schedules: Interconnections permit planned outages of generating and transmission facilities for maintenance to be coordinated so that overall cost and reliability for the interconnected network is optimized. Some costs and benefits of interconnections are difficult to quantify, but as a rough figure of merit it has been estimated that interconnections in North America have resulted in an overall annual cost savings of $20 billion in the 1990s, and that the Western European interconnection has resulted in reduced capacity requirements of 7-10 percent.

2.1.1. Technical complexities and risks of grid interconnections

The fact that interconnections between power systems are increasingly common does not imply that they are as simple as connecting a few wires. Interconnections obviously entail the expense of constructing and operating transmission lines and substations, or in the case of HVDC, converter stations. Interconnections also entail other costs, technical complexities, and risks. For AC interconnections especially, a power system interconnection is a kind of marriage, because two systems become one in an important way when they operate in synchronism. To do this requires a high degree of technical compatibility and operational coordination, which grows in cost and complexity with the scale and inherent differences of the systems involved. To give just one example, when systems are interconnected, even if they are otherwise fully compatible, fault currents (the current that flows during a short circuit) generally increase, requiring the installation of higher capacity circuit breakers to maintain safety and reliability. To properly specify these and many other technical changes required by interconnection requires extensive planning studies, computer modeling, and exchange of data between the interconnected systems. The difficulties of joint planning and operation of interconnected systems vary widely. As with marriages, from the institutional and administrative standpoint, coupled systems may become a single entity, or they may keep entirely separate accounts. Within the North American interconnections, for example, there are hundreds of electric utility companies that are entirely separate commercial entities. Customers receive power from, and pay bills to, the utility that serves their area, for example Consolidated Edison. They may do so without even knowing of the existence of the Eastern interconnection. Yet all the utilities in the Eastern interconnection are in a technical marriage that dictates or constrains key aspects of their technology choices and operating procedures. Within countries, there are typically common technical standards for all utilities, which reduces the complexity of interconnecting separate systems. In different countries, on the other hand, power systems may have evolved quite separately, with very different standards and technologies, which adds an extra layer of technical complexity to interconnections. Institutional and administrative features of power systems in different countries are also likely to differ in many ways, and these differences invariably affect the technical and operational dimensions of an interconnection. Issues ranging from power trading agreements to reliability standards, while expressed in technical terms, often must be resolved within the realm of policy and political economy. As one expert on international interconnections has remarked, “many technical, organizational, commercial and political problems have had to be solved to get large networks linked by international interconnections to operate”11. The greatest benefits of interconnection are usually derived from synchronous AC operation, but this can also entail greater reliability risks. In any synchronous network, disturbances in one location are quickly felt in other locations. After interconnecting, a system that used to be isolated from disturbances in a neighboring system is now vulnerable to those disturbances. As major blackouts in North America and Europe in 2003 demonstrated, large-scale disturbances can propagate through interconnections and result in cascading outages, bringing down systems that had previously been functioning normally. In addition, long-distance interconnections with long transmission lines have potentially greater stability problems than is the case for shorter lines. Finally, many systems that have undergone electricity liberalization in recent years have experienced large increases in transmission capacity utilization, reducing reserve margins. Minimizing the likelihood that an interconnection will lead to such problems as voltage collapse, dynamic and transient instability, or cascading outages due to propagated disturbances requires careful planning and well-coordinated operation.

2.2. Technical parameters of interconnection

2.2.1. Basic Electrical Parameters

This section describes the basic electrical parameters and units of measurement used in electric power systems. It is meant to provide the non-technical reader with the concepts needed for a general understanding of the technical issues discussed in subsequent sections.

AC & DC

Electric power comes in two forms: alternating current (AC) and direct current (DC). These forms are characterized by the behavior of their waveforms: AC alternates between positive and negative polarity with respect to ground, while DC does not. In power systems, AC is generally a sine wave, while DC is a constant value. Early electricity systems, such as Thomas Edison’s Pearl Street Station in New York City, which provided the world’s first public electric service in 1882, were DC. However, by the beginning of the 20th century AC systems had become standard worldwide. The main reason for the adoption of AC was that it is relatively simple to change AC voltage levels by using transformers, while it is difficult to change DC voltages. The development of solid-state power electronics in recent years has allowed an increased use of DC in the form of HVDC interconnections, but otherwise power systems remain AC.

Frequency

Frequency is the rate at which an alternating current changes from positive to negative polarity, measured in cycles per second, or hertz (Hz). There are currently two widespread world standards for power system frequency: 50 Hz in most of Europe and Asia, and 60 Hz in North America and in other places strongly influenced by the U.S. power industry, such as South Korea. The choice of 50 and 60 Hz systems in different locations is a consequence of historical legacies rather than the inherent technical superiority of one or the other. However, the range of possible frequencies for power systems is constrained by practical concerns. For example, a century ago many electric railroads operated at a frequency of 25 Hz, but 25 Hz was never adopted for general use in power systems because frequencies at that level cause electric lights to flicker. At the other end of the scale, frequencies well above 60 Hz result in higher impedances, leading to unacceptably high transmission and distribution losses.

Voltage

Voltage is the difference in electric potential between two points in an electric circuit. A difference in potential causes electric charges to flow from one place to another, just as a difference in heights causes water to flow from one level to another. Voltage is measured in volts (V), and sometimes in thousands of volts or kilovolts (kV). In power systems, two important measures are the maximum voltage and average voltage at any particular point. Maximum voltage is important because insulation and safety equipment must be designed to protect against the highest voltage encountered. Average voltage is important because the amount of energy supplied to an end user or lost in transmission lines is a function of the average voltage and current. For DC systems, maximum and average voltages are the same, because DC voltage doesn’t oscillate. For example, the output of a 120 V DC power supply is a continuous 120 V relative to ground, and this is both the maximum and average voltage. For AC systems, different measures are required. In a 120 V AC system, the voltage actually oscillates in a sine wave between + 170 V and – 170 V relative to ground. The maximum voltage, also called amplitude or peak voltage, is thus 170 V. The simple arithmetic average of this waveform is actually 0 V, since the positive and negative voltages cancel each other out. Hence, another type of average is used, called root-mean-square (RMS). RMS is obtained by squaring the values of the voltage over one complete sine-wave cycle, determining its average value, and then taking the square root of that average. The result (true for any sine wave) is that VRMS = VPEAK / √2 = 0.707 VPEAK. For a household system with a VPEAK = 170 V, VRMS = 0.707 (170 V) = 120 V. Thus the common designation of a household electric outlet as “120 V AC” refers to the RMS value of the voltage. The voltages of power system components, such as transformers and transmission lines, are also generally given in RMS terms.

Current

Current is the flow rate of electric charge. In an electric circuit, charge flows from a point of higher voltage to a point of lower voltage through a conductor, just as water flows from a higher spot to a lower one through a pipe. Current is measured in amperes (A) or kilo-amperes (kA), where one ampere is a certain number of charges (to be precise 6.25 x 1018 charges, called one coulomb) flowing per second. As is the case for voltage, AC currents are generally described in terms of their RMS values.

Resistance and Conductance

Conductance describes the ability of an object, such as an electric wire, to allow electric currents to flow. The reciprocal of conductance is resistance, which describes how much the object resists the flow of current. Resistance is measured in ohms (Ω). The resistance of wire is a product of its resistivity (an inherent property of the material from which it is made, such as copper or aluminum, for a given temperature) and the dimensions of the wire. For a given material, the longer the wire is, the greater the resistance, and the larger in diameter the wire is, the smaller the resistance. In the analogy of water flowing from a higher to a lower spot through a pipe, resistance is analogous to the friction of the pipe. A narrow pipe has a higher resistance; a wide pipe has a lower resistance.

Ohm’s Law

Ohm’s Law describes the relationship between voltage (V), current (I), and resistance (R) across any element of a DC electric circuit: V = I∗R. Thus, for a fixed value of resistance – say for an HVDC transmission line of a certain length and diameter – if the voltage is made larger, the current will decrease, and vice versa. For example, if the resistance of a line is 25 Ω, and the current through the line is 1 kA, then the voltage drop across the line is V = 1 kA * 25 Ω = 25 kV. If the voltage on the sending side was 500 kV, then the voltage on the receiving side must be 25 kV less, or 475 kV.

Power and Energy

Power is the rate of energy flow, measured in watts (W), and sometimes in thousands of watts or kilowatts (kW), or in millions of watts or megawatts (MW). For a DC circuit, the power passing through any element of the circuit (e.g. a transmission line, a generator, an electrical appliance) is the product of the voltage across it and the current passing through it: P = I∗V. The energy delivered by a power system is measured in kilowatt-hours (kWh), and sometimes megawatthours (MWh). In general, energy is equal to power times time. For example, a light bulb that draws 100 W of power and is in use for 10 hours consumes a total amount of energy, E = 0.1 kW * 10 h = 1 kWh. Note that power and energy are quite different concepts. If an electric oven draws 1 kW of power and is in use for an hour, E = 1 kW * 1 h = 1 kWh. In these two examples, the power levels are different but the energy consumed is the same, the difference being the length of time that each device is operated. Note that the basic unit of energy is the joule (J), while the basic unit of power is the watt, where 1 W = 1 J/s. Thus 1 kWh = 1 kW * 1 h = 1000 J/s * 3600 s = 3.6 million J.

Resistive Losses

When current flows against a resistance, some of its energy is lost in the form of heating. For a DC circuit, the resistive losses can be calculated using Ohm’s Law: PLOSS = I∗V = I(I/R) = I2R. To continue with the example under “Ohm’s Law” above, consider a 500 kV HVDC transmission line with 25 Ω of resistance, with 1 kA of current passing through it, and which has a voltage on the sending end of 500 kV, and a voltage on the receiving end of 475 kV. The total power being transmitted at the sending end of the transmission line is P = 500 kV ∗ 1 kA = 500 MW. Out of this 500 MW, the amount being lost to heating is PLOSS = (1 kA)2 ∗ 25 Ω = 25 MW. This constitutes 25 MW/500 MW = 5 percent of the power being transmitted. Very high voltages are used in transmission in order to reduce resistive losses to a tolerable level. In the example above, if the same amount of power were being transmitted (500 MW) but the sending voltage were 125 kV instead of 500 kV, the current through the line must be I = P/V = 500 MW/125 kV = 4 kA; the current is four times higher to yield the same amount of power, because the voltage is four times less. The power lost in the transmission line is then PLOSS = (4 kA)2 ∗ 25 Ω = 400 MW = 80 percent of the power being transmitted. In general, line losses are inversely proportional to the square of the sending voltage; this is true for AC lines as well as DC. For this reason, historically power systems have sought to increase their transmission voltages as distances and amounts of power transmitted have grown. The highest common AC transmission voltages, sometimes referred to as extra high voltage (EHV), are 380 kV in Europe and 765 kV in the US. Voltages as high as 1200 kV have been used in Russia for some long-distance lines across Siberia. Above 1000 kV, however, the practical difficulty and expense of equipment and insulation that can withstand such high voltages becomes prohibitive.

Impedance, Reactance, Inductance, Capacitance

AC circuits involve not only resistance but other physical phenomena that impede the flow of current. These are inductance and capacitance, referred to collectively as reactance. When AC currents pass through a reac tance (e.g. in transmission and distribution lines, in transformers, or in end-use equipment such as electric motors) some of the energy is temporarily stored in electro-magnetic fields. This has three important implications. (1) Even though energy is not “lost” to the environment as in the case of resistive heating, it must still be supplied to the reactive elements. This is known as reactive power. (2) Voltage decreases when current flows across a reactance, just as it does across a resistance. For AC circuits, Ohm’s Law must be modified: V = I∗Z, where Z is the sum of resistance and reactance, called impedance, and is measured in ohms. (3) V, I, and Z are all complex numbers, meaning that they express not only magnitudes in volts, amps, and ohms, but also phase angles. Voltage and current waveforms both oscillate at same frequency - either 50 Hz or 60 Hz depending on the system – but they can differ in terms of the angular location within a cycle at which the maximum voltage or current occurs. This difference in angular location is referred to as phase difference, often symbolized by φ (phi) or θ (theta) and measured in degrees (or radians). Passing through an inductance causes an AC current waveform to fall behind, or lag, the voltage waveform. Passing through a capacitance causes AC current to move ahead of, or lead, the voltage. Equivalent amounts of capacitance and reactance cancel each other out.

Complex Power: Real, Reactive, Apparent

For AC systems, there are three kinds of power: real, reactive, and apparent. Real power (sometimes called active power) is what is consumed by resistances, and is measured in W (or kW, or MW). Reactive power is consumed by reactances, and is measured in volt-amperes reactive, or VAR (sometimes kVAR, or MVAR). Apparent power is the complex sum of real and reactive power, and is measured in voltamperes, or VA (or kVA or MVA). S = √(P2 + Q2), where S is apparent power, P is real power, and Q is reactive power. Apparent power is what must be supplied by the generators in a power system to meet the system’s electrical load, whereas end-use is generally measured in terms of real power only. Utilities always seek to minimize reactive power consumption, among other reasons because it is difficult to measure and be compensated for reactive power by customers.

Loads and Power Factors

An electrical load is the power drawn by an end-use device or customer connected to the power system. (Sometimes, “load” is used to refer to the end-use devices or customers themselves, but among engineers it usually refers to the power demand.) Loads can be resistive or reactive, and are often a combination of both. The extent to which a load is resistive is measured by its power factor, (p.f.), which is equal to the cosine of the phase difference between the current and voltage through the load: p.f. = cos φ. When the power factor is at its maximum value of one, the load is purely resistive. On the other hand, the smaller the power factor, the greater the phase difference and the greater the reactive power component of the load. Inductive loads, such as electric motors, have a lagging power factor (see 2.1.9), and are said to consume reactive power. Capacitive loads have a leading power factor and are said to be sources of reactive power. Given the voltages and currents through a circuit element, apparent, real, and reactive power can be calculated respectively as follows: S = IRMS * VRMS P = S * p.f. = IRMS * VRMS * cos φ Q = IRMS * VRMS * sin φ

Reactive loads can have a large effect on line losses, because the current flowing through a line, and the associated heating, is a function of the apparent power S rather than the real power P. For example, consider a load of 150 kW with a lagging power factor of 0.75, which is supplied by a 10 kV distribution line with a resistance of 10 Ω. The apparent power drawn by the load is S = P/p.f. = 150 kW/0.75 = 200 kVA. The current to the load is then I = 200 kVA/10 kV = 20 A. The line loss is PLOSS = I2 * R = (20 A)2 * 10 Ω = 4 kW. If there were no reactive power consumption by the load, the power factor would be equal to one. In that case, S = P = 150 kW. Then I = 150 kW/10 kV = 15 A, and PLOSS = (15 A)2 * 10 Ω = 2.25 kW. Thus the reactive load in this example increased the line losses from 2.25 kW to 4 kW, an increase of 78 percent.

Three-Phase Systems

House current is generally single-phase AC power, but the rest of the power system from generation to secondary distribution employs 3-phase AC. This means that transmission lines have three separate conductors, each carrying one-third of the power. The waveforms of the voltage in each phase are separated by 120°. There are two major reasons that 3-phase power became dominant. (1) As long as the electrical loads on each phase are kept roughly balanced, only three wires are required to transmit power. Normally, any electric circuit requires both an “outbound” and “return” wire to make a complete circuit. Balanced 3-phase circuits provide their own return, and thus only three, rather than six, wires are required to transmit the same amount of power as three comparable single-phase systems. (2) Since the invention of polyphase induction motors by Nikola Tesla in the 1890s, 3-phase motors have been the workhorse of industry. More than one phase is required to balance torque, which increases the effectiveness and lifetime of both motors and generators. Voltage and Power in Three-Phase Systems The voltage in 3-phase systems can be specified in two different ways. One is phase to ground, which as it sounds is the voltage between any one of the three phases and ground. The other is phase to phase, which is the voltage between any two of the three phases. Power lines are conventionally described by their phase to phase voltage, also called the line voltage. Phase to phase voltage is greater than phase to ground voltage by a factor of the square root of three. Thus, a 500 kV line has a phase to phase voltage of 500 kV, and a phase to ground voltage of 500 kV/√3 = 289 kV. In both cases, the voltage referred to is the RMS value. The amount of power transmitted in a three-phase system is three times the power in each line. Thus S = 3 (I * VLINE/√3) = √3 I * VLINE, where VLINE is the phase to phase voltage. For example, the apparent power transmitted by a 500 kV circuit with a current of 1 kA is S = √3 * 500 kV * 1 kA = 866 MVA. The real and reactive components can be calculated easily if the load power factor or phase difference is known (see 2.1.10). In this example, if φ = 25°, the real power P = S cos 25° = 866 MVA * 0.906 = 785 MW, and the reactive power Q = S sin 25° = 866 MVA * 0.422 = 366 MVAR.

2.2.2. Basic Design Features

The basic design features of an interconnection include the following elements: • whether it is AC or DC • if DC, whether it is single-pole or double-pole (+/-) • transmission capacity (in MVA) • transmission voltage (in kV) • system components and overall design • operating agreement These features are dictated by the answers to the following questions: • Will the interconnected systems operate synchronously or asynchronously? To operate synchronously, at a minimum the systems must have the same nominal frequency (50 Hz or 60 Hz). Even if frequencies are the same, technical and operational differences can make synchronous operation too difficult or expensive to pursue. Many synchronous networks with the same nominal frequency, including the four North American interconnections, have only asynchronous DC connections between them. • What are the magnitudes and directions of the anticipated power flows? The basic rationales for the interconnection must be expressed quantitatively, using models that forecast the power flows through the interconnection among constituent systems. The forecasts must be conducted on different time scales: diurnal, seasonal, annual, and multi-year projections. • What physical distance and terrain will the interconnection span? The peak power flows and the physical length of the interconnection will influence the choice of AC or DC, the size of conductors, and requirements for other system components, such as series capacitors or phase-shifting transformers. Terrain, geology, and land use considerations (such as urban areas, environmentally sensitive areas) will determine whether overhead lines or underground cables are used, the layout and design of substations or converter stations, grounding and lightning protection schemes, and the most suitable kinds of support structures. Undersea transmission requires the use of special cables that are quite different from terrestrial cables and overhead lines. Terrain and land use also dictate construction and maintenance methods. • What are the key technical and operating differences among the systems to be interconnected? These include differences in the hardware, control systems, and procedures used for frequency regulation, voltage regulation, and fault protection.

2.2.1. Interconnection Elements

A listing of the basic elements of an interconnection is provided below. Technical Objectives The ultimate objective of an interconnection, like the power systems it is part of, is to provide power to customers economically, safely, reliably, efficiently, and with minimal environmental impact. Each of these aspects has one or more quantitative measure, such as price per kilowatt-hour, number and lethality of accidents, frequency and duration of service interruptions, generating plant heat rate, transmission and distribution losses, and emissions factors. Interconnections are designed, and their individual components selected, with all of these objectives in mind, though they may be optimized differently in different systems.

Transmission Lines

Transmission lines come in two basic varieties: overhead lines and underground (or undersea) cables. Overhead lines are more common and generally less expensive than cables. The main design consideration for overhead lines is the choice of conductor type and size, which must balance the need to minimize impedance (and the associated losses), minimize cost, and minimize the weight that must be carried by support structures. Although copper is a better conductor, it has been overtaken in recent years by aluminum, which is lighter, cheaper, and in abundant supply. The most common variety of overhead conductor for high-capacity, long-distance transmission is stranded aluminum wire reinforced with steel (known as ACSR, for “aluminum conductor steel reinforced”). Other design considerations for overhead lines are the type of support structures (such as transmission towers and insulators) used, and the configuration of conductors on the support structures, which affects the reactance of the conductors and the strength of electromagnetic fields (EMFs) around the lines. Underground cables are used where overhead conductors are inappropriate due to environmental or land use considerations, such as in high-density urban areas or ecologically sensitive areas. Cables are insulated and are typically routed through underground conduits, and often require cooling systems to dissipate heat. Cables may use copper instead of aluminum, balancing the greater cost of copper against its superior conductivity and lower resistive heating. Undersea cables are usually made of copper, and may be surrounded by oil or an oil-soaked medium, then encased in insulating material to protect from corrosion. Undersea cables often have a coaxial structure, which has an inherently high capacitive reactance; therefore undersea cables are usually DC, which is not affected by reactance. Conductor cross-sections are typically measured in square centimeters (cm2) in the metric system, or thousands of circular mils (kcmil) in the American system12. The capacity of a conductor to carry current without exceeding thermal limits is called its ampacity, measured in kA for large conductors.

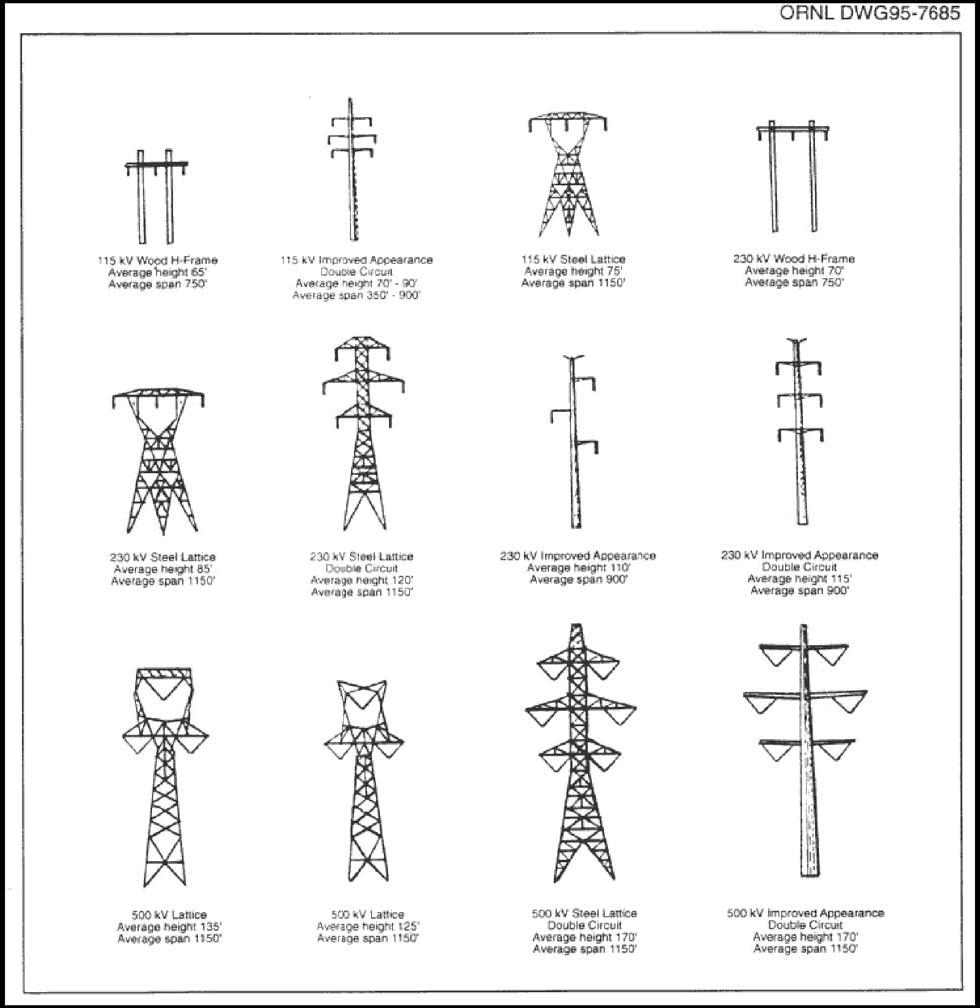

Support Structures

There are many possible types of support structures for overhead transmission lines. In developed countries, transmission lines are supported on structures made out of steel lattice, tubular steel, wood, and concrete. Of these, steel lattice has the highest strength to weight ratio, and is the easiest to assemble in areas that are difficult to access13. Where aesthetics are an important factor, however, other materials are often used. The main function of support structures is to keep the conductors from contacting trees or other objects, including people and animals; thus the structures must be tall enough to do so even when the conductors sag due to high temperatures caused by resistive heating. All things being equal, taller structures also minimize ground-level EMFs. Because overhead transmission lines are not insulated, they are typically suspended from towers on strings of ceramic insulators, which are designed to prevent flashover, or the leakage of current from the conductors to the tower, which would present a lethal prospect to anyone touching the tower. AC transmission towers are usually designed to carry three conductors: the three phases of AC power systems. Towers that hold these in an equilateral triangle shape (called a “delta”) keep the mutual reactances of the three phases balanced; non-delta configurations often require that conductors be transposed, or switch places, at regular intervals along the transmission path. Some towers carry more than one circuit, with three phases per circuit; for example, a double-circuit tower will have six conductors. (The conductor for each phase may also be subdivided into “bundles” of two or more conductors, which are physically close together.) DC transmission towers carry two conductors per circuit. Figure 2-1 on the following page shows various options for transmission tower design.

Transformers and Substations

Transformers are used to change voltage levels in AC circuits, allowing transmission at high voltages to minimize resistive losses, and low voltages at the customer end for safety. This ability, following the development of transformers by William Stanley in 1885, led to the rapid adoption of AC systems over DC systems. The essential element of a transformer consists of two coils of wire wrapped around an iron core. An alternating current in one coil produces a changing electromagnetic field that induces a current in the other. The voltages on either side are in the same ratio as the number of turns on each coil. For example, a transformer with a 10:1 “turns ratio” that is connected to a 15 kV supply on its primary side, will have a voltage of 150 kV on its secondary side. Transformers step up the voltage from generator to transmission system, and other transformers step it down, often in several stages, from transmission to sub-transmission to primary distribution to secondary distribution, and finally to the end-user voltage, such as 120 V. At the distribution level, transformers often have taps that can be used to change the turns ratio; this allows operators to maintain customer voltage levels when system voltages change. Modern transformers are extremely efficient, typically greater than 99%, but even small losses can produce a great deal of heat, which must be dissipated to prevent damage to the equipment. Large transformers are cooled by circulating oil, which also functions as an electrical insulator.

Large transformers are housed in substations, where sections of a transmission and distribution system operating at different voltages are joined. Larger substations have a manned control room, while smaller substations often operate automatically. In addition to transformers, important substation equipment includes switchgear, circuit breakers and other protective equipment (see next section), and capacitor banks used to provide reactive power support.

Protection Systems

Protection systems are an extremely important part of any power system. Their primary function is to detect and clear faults, which are inadvertent electrical connections – that is, short circuits – between system components at different voltages. When faults occur, very high currents can result, typically 2-10 times as high as normal load currents. Since power is proportional to I2, a great deal of energy can be delivered to unintended recipients in a very short time. The goal of protection systems is to isolate and de-energize faults before they can harm personnel or cause serious damage to equipment. Note that protection systems are designed to protect the power system itself, rather than end-user equipment.