Energy input in the Maize value chain in Benin

This page is currently under construction :)

Introduction

Maize production

Worldwide, maize (Zea mays l.) is the most widely cultivated crop with a production of over a billion tons per year and is therefore of very high importance for global food security and livelihoods, especially in developing countries. According to Leroux et al. (2019), maize is the leading staple food in West African countries with a yearly consumption of more than 30 kg/capita. From 2007-2016, yields of rainfed maize systems in Sub Saharan Africa (SSA) range between 1.68 to 1.99 t/ha, which is 15-25% of the yield potential for water-limited production (ten Berge et al., 2019). Maize can be prepared in different forms which include whole-maize foods, porridges or beverages (Ekpa et al., 2018). In, maize is the most important staple food and the most cultivated crop, with 85% of farmers growing it. The area devoted to maize production is about one-third of the total agricultural area in Benin (Amegnaglo, 2018).

Energy and Greenhouse gases (GHG) conversion factors

Maize value chain in Benin

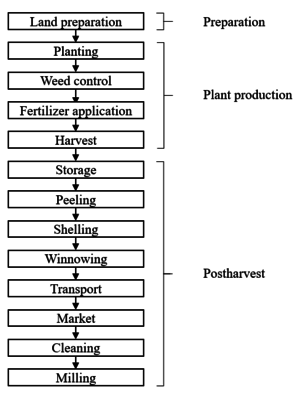

Maize production and processing have different processing steps, most of them are performed sequentially.

Maize production starts with activities of land preparation, where fields are prepared for the planting. The activities include usually the clearing of the fields followed by ploughing.

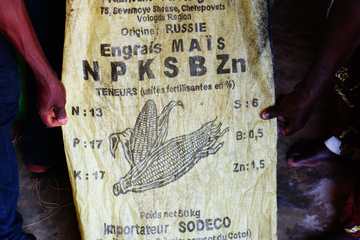

The activities of plant production start with planting with the first rainfalls, as most farming systems in Benin are rainfed. After a given time weed control is done by manual removal of unwanted vegetation, followed by the application of fertilizers, mostly NPK and urea.

Postharvest activities are the processing steps until reaching the final product. The harvested maize is stored in silos and removed and processed when needed to sell on markets or for own consumption.

Smallholder farmers usually do the land preparation and plant production manually, medium-sized farms commonly request the services concerning machinery for land preparation and equipment with or without operator. Large farms usually own the tractors for the cultivation of their crops. Processing of the maize except milling is done on farm level. The milling of maize is done by service providers who operate on village or neighbourhood level.

Land preparation

During the clearing of the fields, bushes and shrubs are cut down manually and removed/burned by workers equipped with machetes. This activity can also be done mechanized. The ploughing is done either manually by farmers equipped with hoes or mechanized with the help of tractors.

The following table shows the labour inputs, when the field preparation activities are done manually. The number of farms indicate on how many farms the data were collected. Labour inputs gives the mean value (and standard deviation) of the total labour of one person required to prepare a field size of one hectare.

| Process |

Number of farms |

Labour inputs (Man-hour/ha) |

|---|---|---|

| Manual clearing |

12 |

137.9 (± 84.2) |

| Manual ploughing |

7 |

181.1 (± 85.2) |

The following table shows the amount of fuel required and the respective machine time for the mechanized clearing and ploughing of one hectare by tractor.

| Process | Number of observations | Fuel (l/ha) | Machine time (h/ha) |

|---|---|---|---|

| Mechanized clearing |

1 |

8.6 |

2.8 |

| Mechanized ploughing |

2 |

13.1 (± 4.9) |

2.3 (± 1.1) |

Plant production

Once the field is prepared, farmers wait for favorable weather conditions before planting. This step occurs with the first rains at the beginning of the rainy season. Holes are put in the soil with hoes and are then filled with seeds. After planting, weeding is done to remove unwanted vegetation, which is followed by the application of fertilizer. Once the maize ears have well developed, farmers leave them on the plants for drying. The processes of plant production are all done manually.

The following table shows the agricultural inputs (seeds and fertilizers) as well as the grain yield per hectare. The number of farms shows on how many farms the data were collected.

| Type |

Number of farms |

Input/outcome (kg/ha) |

|---|---|---|

| Seeds |

12 |

22.0 (± 10.2) |

| NPK fertilizer |

8 |

88.0 (± 33.1) |

| Urea fertilizer |

8 |

69.0 (± 24.2) |

| Maize harvest (grain yield) |

13 |

1786.0 (± 692.9) |

The following table shows the work input in the processes of plant production.

| Process |

Number of farms |

Labor inputs (Man-hour / ha) |

|---|---|---|

| Planting |

13 |

32.6 (± 24.5) |

| Weed control |

13 |

109.3 (± 82.2) |

| Fertilizer application |

9 |

30.6 (± 15.4) |

| Harvest |

12 |

71.9 (± 33.1) |

Postharvest

The ears with husk are harvested and stored in silos. The maize is removed from the silo for own consumption or for selling in the local markets. The maize ears are then manually peeled to remove the husk. The separation of the maize grains from the cob is done by using a shelling machine. Then the grains are cleaned by wind winnowing or by using the airflow coming out from the shelling machine. After cleaning, farmers can transport the maize to the market. Before selling, the removal of broken grains and foreign material is performed manually. Consumers buy the grains and transport them to local milling stations, where the grains are transformed into maize flour. Apart from the milling, all processing steps are done individually by farmers.

Cropping calendar

Energy input

Greenhouse gas emissions