Concentrating Solar Power (CSP) - Technology

Overview

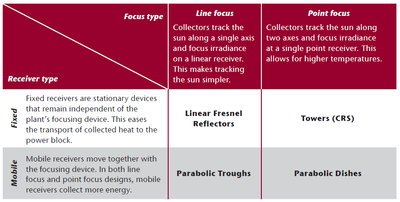

In CSP power plant design there are four main collector technologies that are being applied. These technologies have to be picked site-specific and shall be discussed here. A good overview is provided by the International Energy Agency in its Technology Roadmap on Concentrating Solar Power.

CSP technology, being quite different from the more popular photovoltaic equpiment, concentrates sunlight to effectively create heat to raise steam. However, there are different types of technology working under title of CSP. In the following chapters, the idea of the “parabolic trough”, the “power tower”, the “Fresnel mirror system” (or simply “linear Fresnel”) and the “dish” will be presented.

Parabolic Trough

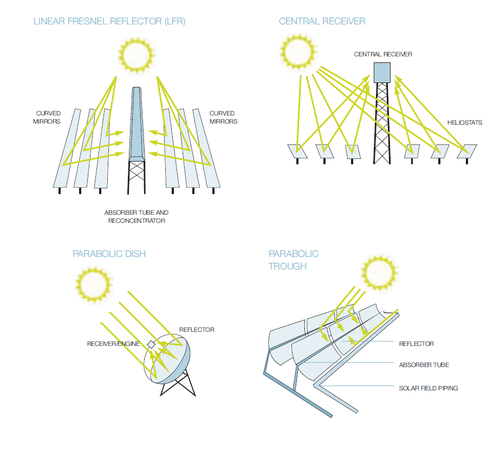

These receivers are mobile applications. They are moving on a 1-axis-tracking system according to the sun's movement. It is a simpler application for tracking the sun than a point focus system (power tower or dishes) that needs to track the sun along two axes. This system, however, consists of parallel rows of reflectors or mirrors. Absorber tubes made of stainless steel serve as the heat collectors. The selective coating on these absorber tubes allows to absorb high levels of solar radiation while only few energy is lost again through infra-red radiation. The absorber tubes are insulated in an evacuated glass envelope. The heat transfer fluid used is synthetic oil. The oil is transferred through the tubes to a heat exchanger which heats and then superheats water into superheated steam. The steam is then expanded in a turbine which runs a generator to produce electricity. The water is then cooled, condenses and returns to the heat exchangers.

Power Tower

The power tower really lives up to its promise. Compared to other CSP technologies, it can create the highest degree of temperature. Surrounded by mirrors reflecting light onto an elevated and centered tower, the power tower generates heat of about 1,000 C°.[1] By transferring the reflected concentrated solar radiation to a fluid, steam is being produced that expands on a turbine in order generate the intended electricity.[2]

Linear Fresnel

This technology uses flat mirrors that are concentrating on one focal point. Water flows through the pipe which runs directly through the focal point of the mirrors. The Linear Fresnel arrangement approximates the parabolic shape of trough systems. It is a simple receiver design that facilitates direct steam generation. Thus, heat transfer fluids are not needed while applying this technology.

Dish / Engine

Parabolic dishes concetrate the sun's rays at a focal point in the centre of the dish. Most dishes use a 1-axis-trackig system, predominantly from north to south. The sun's energy, concentrated in the focal point, is given to a heat transfer fluid which is heated up to 750°C. Sometimes even gas transfer systems are applied. The fluid or gas is then used to drive a micro turbine or Stirling engine which is attached to the receiver.

Comparison

| and Technology CSP#Parabolic Trough Parabolic Trough |

and Technology CSP#Power Tower Central Receiver/ Power Tower |

and Technology CSP#Dish / Engine Parabolic Dish |

and Technology CSP#Linear Fresnel Fresnel Linear Reflector | |

|---|---|---|---|---|

| Applications |

Grid-connected plants, mid to high-process heat (Highest single unit solar capacity to date: 80 MWe. Total capacity built: over 500 MW and more than 10 GW under construction or proposed) |

Grid-connected plants, high temperature process heat (Highest single unit solar capacity to date: 20 MWe under construction, Total capacity ~50MW with at least 100MW under development) |

Stand-alone, small off-grid power systems or clustered to larger gridconnected dish parks (Highest single unit solar capacity to date: 100 kWe, Proposals for 100MW and 500 MW in Australia and US) |

Grid connected plants, or steam generation to be used in conventional thermal power plants. (Highest single unit solar capacity to date is 5MW in US, with 177 MW installation under development) |

| Advantages |

• Commercially available – over 16 billion kWh of operational experience; operating temperature potential up to 500°C (400°C commercially proven) • Commercially proven annual net plant efficiency of 14% (solar radiation to net electric output) • Commercially proven investment and operating costs • Modularity • Good land-use factor • Lowest materials demand • Hybrid concept proven • Storage capability |

• Good mid-term prospects for high conversion efficiencies, operating temperature potential beyond 1,000°C (565°C proven at 10 MW scale) • Storage at high temperatures • Hybrid operation possible • Better suited for dry cooling concepts than troughs and Fresnel • Better options to use non-flat sites |

• Very high conversion efficiencies – peak solar to net electric conversion over 30% • Modularity • Most effectively integrate thermal storage a large plant • Operational experience of first demonstration projects • Easily manufactured and mass-produced from available parts • No water requirements for cooling the cycle |

• Readily available • Flat mirrors can be purchased and bent on site, lower manufacturing costs • Hybrid operation possible • Very high spaceefficiency around solar noon. |

| Disadvantages |

• The use of oil-based heat transfer media restricts operating temperatures today to 400°C, resulting in only moderate steam qualities |

• Projected annual performance values, investment and operating costs need wider scale proof in commercial operation |

• No large-scale commercial examples • Projected cost goals of mass production still to be proven • Lower dispatchability potential for grid integration • Hybrid receivers still an R&D goal |

• Recent market entrant, only small projects operating |

| Source: International Concentrating Solar Power Global Outlook Greenpeace International 2009 | ||||

Storage Techologies

Using different approaches to store the excess solar energy into thermal energy storages (TES) it is possible to run a CSP plant around the clock, 24 hours a day and therefore in baseload. For storing thermal energy so-called Phase Change Materials (i.e. water) are applied to make use of the latent heat. In addition thermal-chemical storages can offer even higher storage capacities making use of the chemical reactions taking place due to adsorption and absorption. A commonly used TES is molten salt while other TES are currently under investigation (see SunShot Initiative).

References