Electricity Generation from Biogas

Introduction

Biogas technology, the generation of a combustible gas from anaerobic biomass digestion, is a well-known technology. There are already millions of biogas plants in operation throughout the world.

Whereas using the gas for direct combustion in household stoves or gas lamps is common, producing electricity from biogas is still relatively rare in most developing countries. In Ger-many and other industrialised countries, power generation is the main purpose of biogas plants; conversion of biogas to electricity has become a standard technology.

This document will discuss the potentials, obstacles and necessary framework conditions for the utilisation of biogas for small and medium scale electricity generation in developing coun-tries. This paper will not address the biogas production process in general but focus uniquely on electricity generation.

The findings presented here are based mainly on available experience from GTZ-related pilot biogas power plants in different countries. They focus on more or less well-documented ex-isting country cases even though little extensive documentation of practical long term operat-ing experience is available. Besides the cases described here, we know of further examples from other GTZ projects (e.g. Bolivia, Tunisia and the Ivory Coast). However, there is not yet sufficient information concerning these to merit inclusion in this assessment.

The Technology

Biogas is gas resulting from an anaerobic digestion process. A biogas plant can convert ani-mal manure, green plants, waste from agro industry and slaughterhouses into combustible gas. For further information on the biogas production and fermentation process please refer to the Biogas Portal on Energypedia.info: http://www.energypedia.info/index.php/Portal:Biogas

Biogas can be used in similar ways to natural gas in gas stoves, lamps or as fuel for engines. It consists of 50-75% methane, 25-45% carbon dioxide, 2-8% water vapour and traces of O2 N2, NH3 H2 H2S. Compare this with natural gas, which contains 80 to 90% methane. The en-ergy content of the gas depends mainly on its methane content. High methane content is therefore desirable. A certain carbon dioxide and water vapour content is unavoidable, but sulphur content must be minimised - particularly for use in engines.

The average calorific value of biogas is about 21-23.5 MJ/m³, so that 1 m³ of biogas corre-sponds to 0.5-0.6 l diesel fuel or about 6 kWh (FNR, 2009).

The biogas yield of a plant depends not only on the type of feedstock, but also on the plant design, fermentation temperature and retention time. Maize silage for example - a common feedstock in Germany - yields about 8 times more biogas per tonne than cow manure.

In Germany, cow manure and energy crops are the main forms of feedstock. About 2 live-stock units (corresponding to about 2 cows or 12 rearing pigs) plus 1 ha of maize and grass are expected to yield a constant output of about 2 kWel (48kWhel per day).

In the South Asian context, ESMAP uses a typical specific input-output relation of about 14 kg of fresh cattle dung (the approximate production of one cow on one day) plus 0.06 l diesel fuel to produce 1kWh electricity.

Conversion to Electricity

Theoretically, biogas can be converted directly into electricity using a fuel cell. However, very clean gas and an expensive fuel cell are necessary for this process. This is therefore still a matter for research and is currently not a practical option.

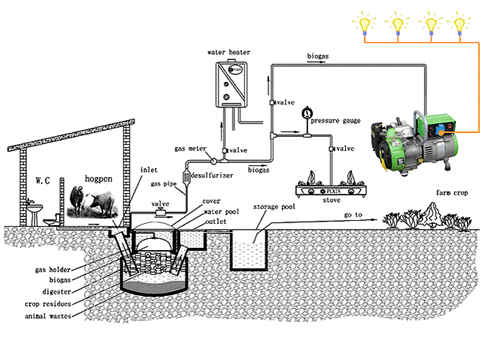

Schematic of a biogas plant used for power generation. Source: www.Greenpower.cn

In most cases, biogas is used as fuel for combustion engines, which convert it to mechanical energy, powering an electric generator to produce electricity.

Appropriate electric generators are available in virtually all countries and in all sizes. The technology is well known and maintenance is simple. In most cases, even universally available 3-phase electric motors can be converted into generators.

Technologically far more challenging is the first stage of the generator set: the combustion engine using the biogas as fuel. In theory, biogas can be used as fuel in nearly all types of combustion engines, such as gas engines (Otto motor), diesel engines, gas turbines and Stirling motors etc.

Gas turbines are occasionally used as biogas engines, especially in the US. They are very small and can meet strict exhaust emissions requirements. Small biogas turbines with power outputs of 30-75 kW are available on the market, but are rarely used for small-scale applications in developing countries as they are expensive. Furthermore, due to their spinning at very high speeds and the high operating temperatures, the design and manufacturing of gas turbines is challenging and maintenance requires specific skills.

External combustion engines such as Stirling motors have the advantage of being tolerant of fuel composition and quality. They are, however, relatively expensive and characterised by low efficiency. Their use is therefore limited to a number of very specific applications.

In most commercially run biogas power plants today, internal combustion motors have become the standard technology either as gas or diesel motors.

Appropriate Combustion Engines

In general, diesel engines operate on biogas only in dual fuel mode. To facilitate the ignition of the biogas, a small amount of ignition gas - often diesel fuel - is injected together with the biogas. Modern pilot injection gas engines (“Zündstrahlmotoren”) need about 2% additional ignition oil. Almost every diesel engine can be converted into a pilot injection gas engine. The advantage of these motors running in dual fuel mode is that they can also use gas of low heating value. However, in such cases, they consume a considerable amount of diesel. Up to engine sizes of around 200kW, pilot injection engines seem to have an advantage over gas motors due to their slightly higher efficiency (3-4% higher) and lower investment costs.

By contrast, gas motors with spark ignition (Otto system) can operate solely on biogas. In practice, a small amount of petrol (gasoline) is often used to start the engine. This technology is used for very small generator sets (~ 0.5-10 kW) as well as for large power plants. Especially in Germany, these engines are advantageous as they do not require additional fossil fuels, leading to lower feed-in tariffs according to the Renewable Energy Law (EEG).

Today, experience of the use of combustion motors to produce electricity from biogas is extensive; this can be regarded as a proven standard technology. Over 4,000 biogas plants with internal combustion motors are in operation in Germany.

However, it has taken lengthy and determined effort to make this technology as durable and reliable as it is today. Internal combustion motors have high requirements in terms of fuel quality. Harmful components - especially hydrogen sulphide (H2S)¬ - in the gas can shorten the lifetime of a motor considerably and cause serious damage. This must be addressed in two ways:

• Production of clean biogas; and

• Use of appropriate and robust motors and components.

In theory, most engines originally intended for cars, trucks, ships or stationary use can run on biogas as fuel and are available almost everywhere within a power range between 10 and 500 kW. This holds true especially in the case of dual fuel use. Robust engines with a certain sulphur resistance are mostly free of non-ferrous metal (German: “Buntmetalle”), as these materials are highly prone to damage through sulphur-rich biogas.

Appropriate Gas Quality

For use in gas or diesel engines, the gas must fulfil certain requirements: • The methane content should be as high as possible as this is the main combustible part of the gas; • The water vapour and CO2 content should be as low as possible, mainly because they lead to a low calorific value of the gas; • The sulphur content in particular, mainly in form of H2S, must be low, as it is converted to corrosion-causing acids by condensation and combustion.

The water vapour content can be reduced by condensation in the gas storage or on the way to the engine.

The reduction of the hydrogen sulphide (H2S) content in the biogas can be addressed via a range of technical methods. These can be classified as chemical, biological, or physical and divided into internal and external methods. Much experimentation has been carried out in the last two decades. However, as complete elimination is unnecessary for use in robust engines, the following simple methods have generally established themselves as standard:

• An optimised steady fermentation process with continuous availability of appropriate feedstock is important to produce a gas of homogenous quality. • The injection of a small amount of oxygen (air) into the headspace of the storage fermenter leads to oxidation of H2S by microorganisms and hence the elimination of a considerable part of the sulphur from the gaseous phase. This is the most frequently used method for desulphurisation. It is cheap and can eliminate up to 95% of the sulphur content in the biogas. However, the right proportioning of air still seems to be a challenge. • Another option is external chemical treatment in a filter. The active material may be: o Iron-hydroxide: Fe (OH)2 + H2S -> FeS + 2 H2O. This process is reversible and the filter can be regenerated by adding oxygen. Adsorption material may be iron-rich soils, waste material from steel or aluminium production; o Activated carbon: Certain companies provide activated carbon filters as a standard component in their gensets. Standard quality sulphur filters and filter material can be purchased on the market.