Difference between revisions of "Wind Energy - Water Desalination"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 337: | Line 337: | ||

2,07<br> | 2,07<br> | ||

| + | |} | ||

| + | |||

| + | The principal advantages of the Enercon desalination unit are its (according to the manufacturer) relatively low energy consumption, its adaptability to fluctuating wind conditions, and the fact that no chemical pretreatment of the raw water is required.11 The plant is compared with mechanical vapour compression technology, for which investment costs are estimated to be somewhat higher and energy consumption somewhat lower than for the WindDesalter design. <br> | ||

| + | |||

| + | The results of the sample calculation show relatively low water production costs, with the reverse osmosis plant being the slightly cheaper variant at 1.32 EUR/m3. The low water production costs can be explained by the relatively low specific energy consumption and the good utilisation rate. Nevertheless, providing additional diesel-generated power could slightly reduce average water production costs for the reverse osmosis plant, even at specific costs of 186 EUR/MWh, thanks to better utilisation of the installed desalination capacity. The additional consumption of diesel-generated power would not be worthwhile for vapour compression, however, as the specific costs of diesel backup are higher than the production costs in island mode. <br> | ||

| + | |||

| + | Table 5 shows the makeup of the production costs estimated for the EDS SW 1200 reverse osmosis plant.<br> | ||

| + | |||

| + | {| height="171" cellspacing="1" cellpadding="1" border="1" width="601" style="" | ||

| + | |+ '''Table 5: Estimated production costs for Enercon EDS SW 1200 - reversed osmosis''' | ||

| + | |- | ||

| + | | <br> | ||

| + | | <br> | ||

| + | | <br> | ||

| + | |- | ||

| + | | Production costs wind energy [EUR/MWh]<br> | ||

| + | | 65,70<br> | ||

| + | | <br> | ||

| + | |- | ||

| + | | Production costs product water [EUR/m<sup>3</sup>]<br> | ||

| + | | 1,32<br> | ||

| + | | <br> | ||

| + | |- | ||

| + | | Investment costs [EUR/m<sup>3</sup>]<br><br><br><br><br><br><br><br><br><br><br><br><br><br> | ||

| + | | 0,64<br> | ||

| + | | 48,63%<br> | ||

| + | |- | ||

| + | | Membrane replacement costs [EUR/m<sup>3</sup>]<br> | ||

| + | | 0,13<br> | ||

| + | | <br>9,54%<br> | ||

| + | |- | ||

| + | | Operating and maintenance costs [EUR/m<sup>3</sup>]<br> | ||

| + | | 0,13<br> | ||

| + | | 9,87%<br> | ||

| + | |- | ||

| + | | Chemicals [EUR/m<sup>3</sup>]<br> | ||

| + | | 0,00<br> | ||

| + | | 0,00%<br> | ||

| + | |- | ||

| + | | Energy costs [EUR/m<sup>3</sup>]<br> | ||

| + | | 0,42<br> | ||

| + | | 31,96%<br> | ||

|} | |} | ||

<br> | <br> | ||

Revision as of 07:24, 21 June 2011

Water desalination: an overview

Of all the water present on Earth, 96.5% consists of seawater. The remaining 3.5% is freshwater, but half of that is tied up in ice and consequently not usable. All in all, significantly less than 1% of the world’s water resources are exploitable as drinking water.

Drinking water is characterised by a high degree of purity, which among other things means a low salt content. There are often directives and regulations governing the permissible salt content in drinking water (such as the Drinking Water Ordinance in Germany). According to the limit defined by the World Health Organisation1, a salt content of up to 0.5 g/l is harmless to human health. Oc-casionally, though, the opinion is also heard that water with a salt content of up to 1 g/l is drinkable. The distinction between freshwater, brackish water and seawater is equally inconsistent. In Ger-man usage, the term brackish water usually relates to water with a salt content of 1 – 10 g/l, while in the Anglo-Saxon world water is still referred to as brackish if the salt content is as much as 18 g/l. Seawater has an average salt content of 35 g/l, although salinity can vary between 2 and 45 g/l depending on the locality. Whatever the case, obtaining drinking water or service water from salty seawater or brackish water calls for removal of salt (and other minerals) from the untreated raw water. This is done by separating the raw water into product water, with a low salt content, and brine, with a high salt content.

There are numerous desalination methods, some of which have been in use in large plants for over 100 years. The common, tried-and-tested desalination technologies can be divided into thermal methods (distillation or vaporisation processes) and membrane methods (see Table 1). In addition there are simple (solar) evaporation systems and complex techniques, not yet used commercially, such as freezing (water separation) and ion exchange (salt separation).

| Thermal methods |

Market share (2005) |

Membrane methods |

Market share (2005) |

|---|---|---|---|

| Multi-stage flash distillation (MSF) |

36% |

Reverse osmosis (RO)Reverse osmosis (RO) |

46% |

| Multi-effect distillation (MED) |

3% |

Electrodialysis (ED) |

5% |

| Vapour compression (VC) |

5% |

|

In early 2005 there were more than 10,000 desalination plants with a daily output of at least 100 m3 in service world-wide. The plants are situated in coastal locations where there is a shortage of drinking water, or in semiarid/arid areas where only brackish water is available. The principal consumers are towns, cities and local communities (63%). Desalination plants are also occasionally used on ships. However, the total installed desalination capacity of about 36 million m3/day met only just under 0.3% of global demand for fresh water. The majority of installed desalination plants (53%) are used for seawater desalination; 24% operate with brackish water, 9% treat surface water, and 6% are designed for treating wastewater (Pacific Institute, 2006). Roughly half the installed desalination capacity is located in the Middle East, the Persian Gulf and North Africa (Figure 1); thermal methods are preferred there, mostly in conjunction with combined heat and power plants (cogeneration stations). In countries such as Saudi Arabia, Kuwait and the United Arab Emirates, the main source of water is seawater. In the USA, which accounts for 17% of global desalination capacity, mainly brackish water and surface water is treated (70% on the basis of reverse osmosis).

The most common desalination methods

Thermal methods

The underlying principle behind thermal methods is that the raw water is brought to boiling temperature and the condensed steam is separated from the brine. As the boiling point depends on pressure (water evaporates at 100°C under atmospheric pressure), the principle can be applied in several process stages, gradually reducing both pressure and boiling temperature. The lower the pressure, the less thermal energy is needed for evaporation. All thermal desalination methods make use of the thermodynamic principle that the evaporation process can be optimised by reducing pressure and boiling temperature (cf. Wangnick 2001, Pacific Institute 2006).

Mechanical vapour compression (MVC): Of the various thermal methods, above all vapour compression enters into consideration for wind-powered desalination. As with all the thermal methods, in vapour compression evaporation takes place by reducing the boiling temperature as a result of reducing pressure. However, the process heat required for evaporation is normally generated by a mechanical – electrically operated – compressor and not provided by a steam generator. In addition to mechanical vapour compression plants there are also types known as thermo-compression plants which operate with process steam and use several evaporation stages.

Mechanical vapour compression is the only distillation method operated solely with electrical energy. Usually the mechanical plants consist of a single stage, and reach daily capacities of up to 3,000 m3. They are considered to be reliable and have low maintenance requirements (no biofouling or scaling), are simple to operate, and require only little additional outlay on pretreatment and post-treatment of the raw water and product water. Their specific power demand (compressor, feed pump) is in the region of 7 - 12 kWh/m3.

Membrane methods

Reverse Osmosis: This method came onto the market at the end of the 1960s and is based on the idea of reversing the natural tendency to balance the level of concentration between two solutions (osmosis). Reverse osmosis counteracts the osmotic pressure by forcing the salty raw water through membranes in the direction opposite to its “natural” direction of diffusion, leaving the dissolved salt behind. The greater the difference in concentration between the salt solutions in the raw water and the required product water (i.e. the greater the osmotic pressure), the more pressure has to be exerted by reverse osmosis. The amount of electrical energy required for reverse osmosis (usually with high-pressure pumps) therefore rises in direct proportion to the salt water content of the raw water [for a given level of product water quality and product water yield] and to product water yield [for a given salt content in the raw water]. In seawater desalination plants with pressure recovery, specific power consumption (high-pressure pump, feed pump, flushing) ranges between 2.5 kWh/m3 and 7.5 kWh/m3; highly efficient plants are said to consume as little as only 2 kWh/m3. Thanks to modular construction methods, plants vary in size from 100 m3/day to 400,000 m3/day, with specific investment costs of 500 – 1,300 USD/m3/day. There are also micro desalination plants for domestic purposes or mobile use ( 2 litres/minute). Membrane methods such as reverse osmosis are used not only for water desalination, but also for treating wastewater. Depending on the available raw water, the product water yield and the required product water quality, smooth operation of the plants requires more or less elaborate pretreatment of the raw water (filtration and addition of chemicals), regular flushing (in some cases with automatic flushing programmes), frequent replacement of the membranes, avoidance of pressure fluctuations at the membranes (alternating operation), and where applicable post-treatment of the product water (filtration, disinfection).

Important characteristics of the various desalination methods are summarised in Table 2.

| MSF |

MED |

MVC |

RO |

ED | |

|---|---|---|---|---|---|

| Primary energy source |

Steam |

Steam |

Mechanical/ electrical |

electrical |

electrical |

| Max. salt concentration of raw water (g/l) |

100 |

100 |

100 |

43 |

3 |

| Product water yield |

=<50% |

=<50% |

30-50% |

=<50% (brackish water =<85%) |

Brackish water: =< 97% |

| Product water quality (mg/l) |

<10 |

<10 |

<10 |

<500 |

<500 |

Options for wind-powered water desalination

In the following, wind-powered water desalination is taken to mean a combination of a wind energy conversion system and a desalination plant. Although wind energy in this connection is primarily used to operate the desalination unit, any excess energy can also be passed on to other consum-ers, for example in the form of electrical energy, if appropriate via the power grid. However, this study does not consider the case of a wind power plant that is built to feed electricity into a trans-mission grid via which power is also supplied to a desalination plant (regardless of whether or not the wind power plant exists).

As wind energy converters supply mechanical or electrical energy, only vapour compression, re-verse osmosis or electrodialysis come into consideration for wind-powered water desalination. All three desalination techniques have been tested in combination with wind turbines in pilot projects or under R&D conditions. Most of the pilot plants are located in the Mediterranean region (or Ca-nary Islands) and serve the purpose of seawater desalination, using reverse osmosis, with daily capacities of up to 2,500 m3. There have been a handful of tests with electrically powered vapour compression plants (Rügen, Canary Islands). No practical experience has been obtained with va-pour compression or reverse osmosis plants powered by mechanical wind energy. Trials with wind-powered desalination of brackish water using electrodialysis have been carried out on the Canary Islands (Veza 2004).

Despite all the pilot schemes and tests no wind-powered desalination plants have established themselves on the market yet. In addition it must be stated that the experience gathered in pilot projects and tests has mostly only been evaluated for the purposes of academic debate and also is only accessible through such channels, and furthermore that there is still no reliable database available which would allow conclusions to be drawn regarding possible use under the conditions encountered in developing countries.

Operating modes

Wind-powered water desalination plants can be operated in island mode (with or without an addi-tional supply of electrical energy, for example from a diesel generator set) or in grid-parallel mode. The proposal was therefore made to categorise plant configuration according to the proportion of wind energy in the desalination unit’s total energy consumption (Käufler 2006). This would result in systems with a low, medium and high wind penetration rate (extent to which energy needs are met by wind).

Island mode with water storage

What makes the use of wind energy converters appear attractive for water desalination, especially when operating solely in island mode, is the fact that the wind energy can be stored in the form of desalinated water and thus be adapted to meet demand (such as constant daily volumes of drinking water). Water storage facilities mitigate the problem that the wind-dependent load curve of a wind power plant does not necessarily match the time profile of energy demand (or of demand for

product water). Provided there are no lengthy periods of calm or storm, an additional water storage facility to compensate for wind fluctuations causes only little additional cost and would reduce the cost otherwise incurred by alternative solutions such as overdimensioning of the wind power plant (with a high proportion of unusable excess electricity), battery storage or the provision of backup or emergency generating systems. Additional water storage for wind operation means that the storage volume is greater than the storage needs that would be planned anyway to allow for consumption peaks, for example, or for interruptions owing to operational disruptions or to regulate pressure fluctuations in the piping system.

Load fluctuations

Storing water does not, however, solve the technical problem that the desalination plant has to cope with fluctuations in the availability of wind energy when it is directly coupled to the wind power plant (without additional energy sources).7 Load fluctuations do not constitute a significant impedi-ment for vapour compression because the power demand of the desalination unit can be largely adapted to match the availability of wind. In the case of reverse osmosis it is true that a modular design can be used to counter changing wind conditions, but even then a constant operating re-gime is required for the individual modules. Load fluctuations mean that a complex control system is required (frequent startup and shutdown procedures), increasing the risk of material fatigue and faults or failures. A further factor applicable to island mode, irrespective of the need for technical adaptation of the desalination facilities, is that (pronounced) load fluctuations and (long) periods of calm or storm are associated with relatively low levels of capacity utilisation of the desalination unit and consequently increase the specific desalination costs.

Backup by diesel generator or grid-supplied power

One important question therefore is whether the additional costs associated with focusing solely on island mode (technical adaptation of the desalination unit, downtimes, additional water storage facility or lack of constant water supply) can be justified when compared with other practicable so-lutions. However, there is insufficient experience to estimate with any precision the costs and risks involved in variable (island) operation, especially of RO plants. Most wind-powered RO pilot plants have been designed so that they can be run at constant load using additional energy sources (grid-supplied energy or diesel generator). It is questionable, though, whether this design is the result of prior optimisation calculations. The fact that providing backup for wind-powered water desalination plants from the grid or running them in association with diesel generators allows the plants to be operated uniformly or in line with demand, and helps improve their capacity utilisation rate does not necessarily mean that this configuration is always the most advantageous. Conversely, however, it is equally difficult to maintain that the benefit of wind power primarily depends on saving diesel-generated electricity or substituting grid-supplied energy. As shown by numerical examples below, under certain circumstances it may well be worth bringing in relatively expensive diesel or grid power in order to increase the capacity utilisation of a wind-powered desalination plant.

Cost efficiency

As a general principle, wind energy which is specifically more expensive than other available energy sources does not become cheaper by being used for water desalination. On the contrary, economic use of wind energy presupposes that the wind energy is cost-efficient from the outset. It follows, then, that a necessary condition for economic use of wind energy for water desalination is that it at least does not increase the specific energy-related desalination costs. Assumingthat this is the case, the following scenarios can be distinguished:

- Sites where autonomous wind-powered desalination allows provision of acceptable water sup-plies at the lowest possible cost: in this case wind energy would be preferred to other solutions anyway because of its cost advantage. The fact that wind energy thereby implicitly substitutes grid power or diesel power would be a secondary effect that arises from the cost saving.

- Sites where wind energy can be provided more cost-effectively than electricity supplied from the grid or diesel generators, but where supplementing energy allows provision of a product water volume that is constant over time (or demand-driven) and/or improved capacity utilisation of the desalination unit: in this case the most advantageous design variant is the one in which the additional use of grid or diesel power minimises the specific water production costs. Draw-ing grid or diesel power beyond the cost-minimised level would be uneconomic.

Low wind penetration rate

It is difficult to imagine, however, that there are sites where minimal-cost water desalination can be achieved with low wind penetration.8 Why should anyone design a desalination plant to be run mainly on electricity from the grid or diesel generators if wind power is a cheaper energy source? The most obvious explanation would be the lack of availability of sufficient wind resources, although this would be difficult to reconcile with the assumption that wind energy is the most cost-effective energy source. It is also conceivable that, although on an annual average the wind regime could provide for good capacity utilisation of the wind power plant (low wind energy costs), in fact it would only be used to a limited extent for water desalination because of considerable fluctuations in load. Capacity utilisation of the desalination unit would then be extremely low without massive support from the grid or diesel generators. The scenario of a water desalination plant to which a wind energy conversion system is coupled merely in order to save small amounts of external en-ergy is therefore more likely to be ranked among the examples of uneconomic use of wind energy. It would at least be appropriate to doubt the economic efficiency of wind-powered water desalina-tion plants if wind is not their primary energy source.

Excess electricity

If the wind energy conversion system generates electricity and is also connected to a grid, any excess energy not required by the desalination plant could be fed into the grid. If the electricity generated by the wind power plant is cheaper than power from the grid, and if the excess energy can be sold at a price that at least covers the prime costs of the wind energy, the average cost of wind-generated electricity will fall, and hence also the cost of desalination. The same also applies of course if the wind energy is more expensive than the grid power, but excess wind-generated electricity can be sold at a feed-in tariff that covers the costs of generation. In that case, though, wind-powered desalination would of course be an uneconomic proposition: why should a desalina-tion plant be run with wind power if cheaper power is available from the grid?

Plants

As yet there are no commercially available wind-powered desalination plants. Only a few manufac-turers of wind turbines offer their products in turnkey solutions in combination with desalination plants (Enercon, Vestesen), and occasionally also as hybrid wind-diesel systems in conjunction with a desalination unit (Enercon). Otherwise it is mainly engineering companies and consultancies that advertise various plant configurations, although these have not yet been proven in practice (DWC DecRen Water Consult, Synwater, Aerodyn Energiesysteme).

The standard plants on offer are designed for a desalination capacity of between 350 m3/day (En-ercon) and 3,800 m3/day (Vestesen), and can provide greater desalination output up to any re-quired level by adding further desalination modules; in part-load operation they permit desalination output to be slowed down to as little as 100 m3/day. As a rule, the solutions offered by plant manu-facturers and consultancies are based on the reverse osmosis method. Wind-powered desalination plants operating with vapour compression units are offered by a very few consulting engineers (Aerdyn Energiesysteme, WME).

It is barely possible to assess the quality of the few products whose development has reached market release stage because as yet there has been no market launch, let alone the emergence of a market segment. Nor is there any price transparency. The providers do not provide any binding information as to how much the plants cost, or the terms under which they are available. Price estimates have been made in several studies and expert reports, however.

Costs

Because of the lack of market-ready wind-powered water desalination plants, cost estimates are highly speculative in nature. This applies in particular to technology as yet untested under the con-ditions encountered in developing countries. The uncertainties primarily relate to the capital outlay costs and operating costs for the desalination component. Little is known, either, of the practical requirements for operation in developing countries. There are no empirical values for the service life of plant components, operating and maintenance costs, the availability of qualified personnel, or other parameters affecting desalination costs. Although adequate price information is available for the commonly marketed wind energy converters, the additional costs – or if applicable even cost savings – associated with adaptation of the systems and operation in connection with a de-salination unit cannot be reliably estimated.

Accordingly there is considerable variation in the cost estimates used by various experts and institutions in their simulation calculations. For example, estimates of the investment costs for a reverse osmosis plant with a nominal capacity of 1,200 m3/day range from 892 EUR/m3/day (Wind-Desalter Engineering, 2004) to 1,600 EUR/m3/day (Zelji, 2002). For comparable vapour compres-sion plants the range extends from 1,125 to 2,500 EUR/m3/day. There are similarly large differ-ences in the assumptions of plant-specific energy consumption. The spread is less wide, on the other hand, for the assumed costs of the wind energy conversion system (900 – 1,200 EUR/kW for an installed capacity of 600 kW), which is no surprise, as the market for wind energy converters is well developed and transparent.

The various studies not only arrive at different results regarding the water production costs, they also disagree about which wind-powered desalination method is cheaper. Depending on case study and desalination technology, the estimated water production costs range between 0.90 and 1.65 EUR/m3 (Garcia-Rodriguez, 2001), 1.42 and 2.44 EUR/m3 (Zelji, 2002), 1.10 and 1.50 USD/m3 (Forstmeier, 2007) or 1.26 and 3.01 EUR/m3 (WindDesalter Engineering, 2004). Be-cause of the lack of market maturity of wind-powered desalination plants, no evidence-based con-clusions can be drawn as to possible cost trends. It would be premature, however, to assume that the specific costs could fall quickly or markedly. When classifying the existing cost estimates it must also be remembered that they generally only include expenditure on energy and desalination, and disregard the possibly equally considerable ancillary costs of supply and preliminary treatment of the raw water, discharge of the brine, storage of the product water and piping it to the end con-sumers. Accordingly, if end consumer tariffs are to cover costs, they may be well above the mere production costs of the product water, depending on the location.

Wind regime and plant utilisation

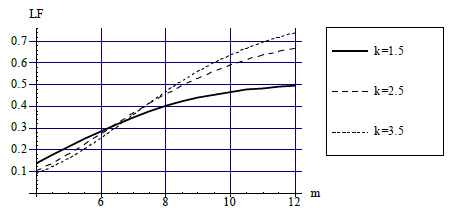

The main difficulty in simulating wind-powered desalination plants has to do with the design of the desalination unit and its utilisation rate that is dependent on the wind regime. For example, cheap wind energy does not necessarily mean low specific desalination costs because the latter depend to a large degree on the utilisation coefficient of the capital-intensive desalination plant. However, given certain plant costs, wind energy can be produced more cheaply the better the installed wind generation capacity is utilised. Figure 2 illustrates the rule of thumb (“good wind conditions”) that the mean wind speed has to be at least 7 m/s for utilisation of the wind energy converter to reach at least 35%. Beyond this “critical” mean wind speed, thoug

h, utilisation depends heavily on the variability of the wind regime, for which the form factor (a parameter of the Weibull distribution) is an indicator. The higher the form factor, the smaller the standard deviation of wind speeds around the mean and the better the capacity utilisation of the plant, especially if the mean wind speed is high.

As the utilisation of the desalination unit is determined not only by the average wind availability but also by its distribution over time, knowledge of the mean wind speed or of the total quantity of en-ergy that can be generated (e.g. annual energy) is not enough to give us any precise information about the utilisation coefficient of a desalination plant matched to the installed wind generation ca-pacity. An approximation of the precise utilisation coefficient can only be calculated by simulating plant operation for a given wind distribution. In the above-cited studies, no such calculations were performed when estimating the desalination costs of wind-powered plants, apart from a few excep-tions (e.g. Paulsen and Hensel, 2007). In some cases there was even an incorrect assumption of 100% utilisation in island mode. Simulations indicate, however, that a utilisation rate of 60 % is more realistic for wind-powered desalination plants without diesel or grid backup, and in fact is a good rate to achieve (Paulsen and Hensel, 2007).

Example: WindDesalter

Table 3 contains estimated figures for water production costs that were calculated on the basis of WindDesalter technology, broken down according to reverse osmosis (RO) and mechanical vapour compression (MVC), in order to illuminate the importance of individual parameters.9 The technical design details of the plants are based on the supplier’s design (Witte 2003, WindDesalter Engi-neering 2004). A list of all the assumptions used here is given in Annex 1.10 The results suggest that in the case under consideration, vapour compression represents the cheaper option (1.76 EUR/m3 compared with 2.08 EUR/m3 for RO) as an island solution, despite its higher specific energy demand (and hence higher energy costs). The cost advantage of vapour compression is derived above all from avoidance of the need to replace membranes and lower consumption of chemicals.

The absolute estimates of water production costs are less interesting than the potential for reduc-ing costs by providing backup from the grid or diesel generation. For both desalination methods the utilisation coefficients of the desalination unit are below 50%, despite favourable wind conditions (WEC load factor: 43%; wind energy prime costs: 53.65 EUR/MWh). The utilisation coefficient of the desalination plants could be improved with the aid of additional energy sources. It is apparent that using additional energy even at the specific cost of 186 EUR/MWh assumed in the example – almost 3.5 times the cost of wind energy – would lower the specific water production costs of the reverse osmosis method (because of greater utilisation of desalination capacity); in the case of vapour compression, on the other hand, desalination would be more expensive on account of this method’s high specific energy consumption. The example illustrates the following fundamental correlation:

- Support from grid power or diesel power is always worthwhile if the variable production costs of the product water that can be obtained with the input of additional energy – i.e. essentially the cost of the additional energy – are lower than the (fixed plus variable) water production costs in purely standalone operation.

| RO |

MVC | |

|

Installed capacity wind power [kW] |

600 |

600 |

|

Annual capacity product water [m3] |

996.450 |

511.000 |

|

Annual production without |

276.593 |

205.160 |

|

Utilisation factor [%] |

27,76% |

40,15% |

|

Additional Annual production with Diesel backup [%] |

10,00% |

10,00% |

|

Additional Annual production with Diesel backup [m3] |

27.659 |

20.516 |

|

Annual production with Diesel backup [m3] |

304.252 |

225.676 |

|

Utilisation factor [%] |

30,53% |

44,16% |

|

Production costs Wind energy [EUR/MWh] |

53,64 |

53,64 |

|

Water production costs: without Diesel backup [EUR/m3] |

2,08 |

1,76 |

|

thereof energy [EUR/m3] |

0,44 |

0,59 |

|

With diesel backup [EUR/m3] |

2,00 |

1,80 |

|

Specific costs Diesel backup [EUR/m3] |

1,22 |

2,13 |

Example: Enercon EDS SW 1200

The estimated water production costs for the reverse osmosis method shown in Table 4 relate to design data for the EDS SW 1200 water desalination plant offered by Enercon, with a daily capac-ity of up to 1,400 m3. As the price of the plant is not known, the costs of the desalination unit have been put at 1,100 EUR/m3/day for illustrative purposes, based on the assumption that this plant type will be specifically more expensive than the reverse osmosis technology proposed for the WindDesalter design.

The estimated water production costs for the reverse osmosis method shown in Table 4 relate to design data for the EDS SW 1200 water desalination plant offered by Enercon, with a daily capac-ity of up to 1,400 m3. As the price of the plant is not known, the costs of the desalination unit have been put at 1,100 EUR/m3/day for illustrative purposes, based on the assumption that this plant type will be specifically more expensive than the reverse osmosis technology proposed for the WindDesalter design.

| RO |

MVC | |

|

Installed capacity wind power [kW] |

600 |

600 |

|

Annual capacity product water [m3] |

511.000 |

255.500 |

|

Annual production without |

296.166 |

177.376 |

|

Utilisation factor [%] |

57,96% |

69,42% |

|

Additional Annual production with Diesel backup [%] |

10,00% |

10,00% |

|

Additional Annual production with Diesel backup [m3] |

27.617 |

17.738 |

|

Annual production with Diesel backup [m3] |

325.782 |

195.113 |

|

Production costs without Diesel backup [EUR/MWh] |

1,32 |

1,44 |

|

Water production costs with Diesel backup [EUR/m3] |

1,26 |

1,49 |

|

Specific costs Diesel backup [EUR/m3] |

0,72 |

2,07 |

The principal advantages of the Enercon desalination unit are its (according to the manufacturer) relatively low energy consumption, its adaptability to fluctuating wind conditions, and the fact that no chemical pretreatment of the raw water is required.11 The plant is compared with mechanical vapour compression technology, for which investment costs are estimated to be somewhat higher and energy consumption somewhat lower than for the WindDesalter design.

The results of the sample calculation show relatively low water production costs, with the reverse osmosis plant being the slightly cheaper variant at 1.32 EUR/m3. The low water production costs can be explained by the relatively low specific energy consumption and the good utilisation rate. Nevertheless, providing additional diesel-generated power could slightly reduce average water production costs for the reverse osmosis plant, even at specific costs of 186 EUR/MWh, thanks to better utilisation of the installed desalination capacity. The additional consumption of diesel-generated power would not be worthwhile for vapour compression, however, as the specific costs of diesel backup are higher than the production costs in island mode.

Table 5 shows the makeup of the production costs estimated for the EDS SW 1200 reverse osmosis plant.

| Production costs wind energy [EUR/MWh] |

65,70 |

|

| Production costs product water [EUR/m3] |

1,32 |

|

| Investment costs [EUR/m3] |

0,64 |

48,63% |

| Membrane replacement costs [EUR/m3] |

0,13 |

9,54% |

| Operating and maintenance costs [EUR/m3] |

0,13 |

9,87% |

| Chemicals [EUR/m3] |

0,00 |

0,00% |

| Energy costs [EUR/m3] |

0,42 |

31,96% |